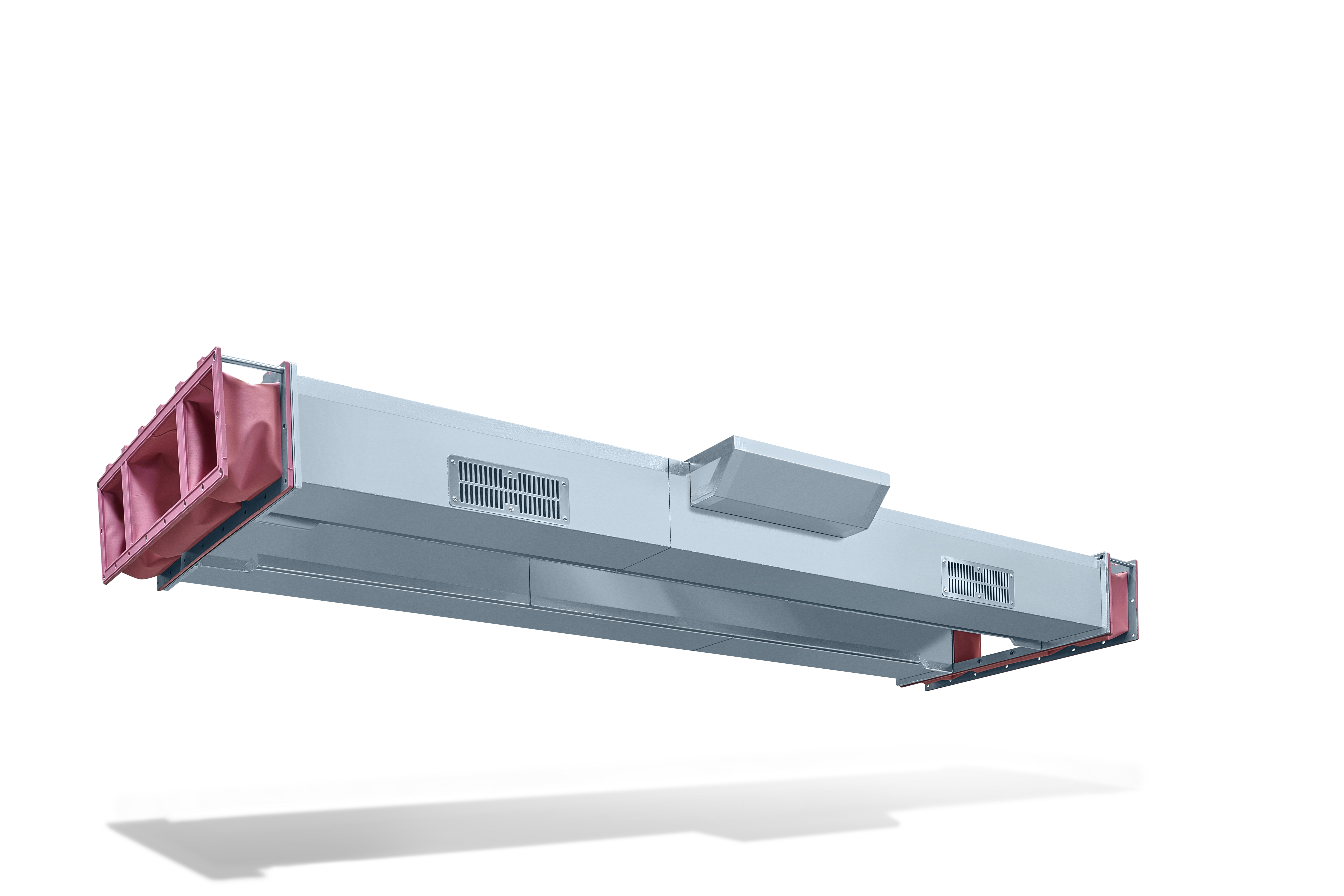

MöllerWerke air duct systems are all manufactured individually according to customer requirements and ensure reliable and uniform air circulation in air-conditioned passenger compartments as well as driver’s cabs. Depending on customer requirements, the air ducts can be made of sandwich material or fiber composite panels. The 12 mm thick sandwich material, which has an insulating core, consists of PU foam laminated on both sides with an aluminium foil. The air ducts made of lightweight and fire-resistant fiber composite panels, on the other hand, are available in thicknesses from 4 mm to 20 mm. Both materials meet the fire protection standard according to EN 45545-2 and are also classified according to R1/HL3.

The air duct systems have a wide range of applications with regard to temperature fluctuations and have been developed for operating temperatures from -40°C to +80°C. In addition, the material meets the fire protection standard according to EN 45545-2 and is classified regarding to R1/HL3. Due to the hazard level 3 classification there are no restrictions in the operation area.

MöllerWerke is a certified adhesive specialist according to DIN 6701. In the certified production area, the cut segments are assembled to a duct system. On customer request, the air ducts can be completed with further applications such as brackets, cleaning openings or interfaces for compensators.

In the company’s own test laboratory, the air ducts can be tested according to DIN EN 61373. MöllerWerke also offers the organisation of testing regarding other international standards as well as customer-specific requirements.

No matter whether tram, regional or express train – MöllerWerke equips your vehicle with individual air duct systems.