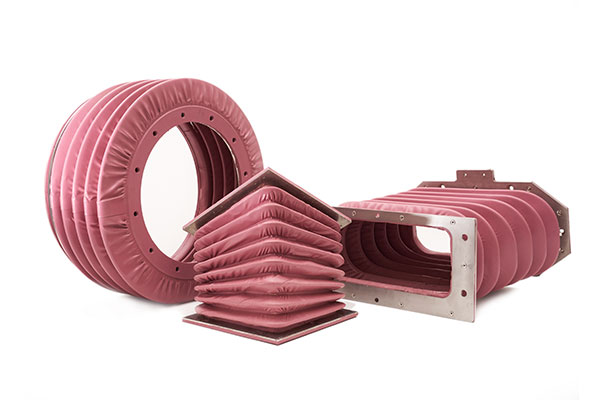

Depending on the interfaces on the vehicle body or bogie, connection systems (e.g. quick-release systems) are implemented in the design according to customer’s request. The connections (flanges) of the bellows have circumferential sealing surfaces. Backing flanges, which are vulcanized to the bellows, create an easy-to-install, secure and tight connection.

MöllerWerke traction motor boots are made of a durable specially developed robust silicone aramid fabric which is certified according to national and international fire standards for railway bellows. These include the fire protection classes according to DIN EN 45545-2 and NFPA 130 (as well as other standards on request). In addition, MöllerWerke traction motor boots are cold-resistant up to -50°C and can withstand a maximum continuous temperature up to +180°C. Apart from that the traction motor boots have optimized abrasion resistance and high resistance to environmental influences, greases and oils.

The maximum stipulated movement as well as the wear and tear of a bellow for a new project is tested under laboratory conditions with testing facilities in the MöllerWerke technical centre, documented and released for serial production. Thereby the wear behaviour with various installation lengths and deformation sequences can be tested as well.